|

Author

|

Topic: My personal Apollo story (Dan Schaiewitz)

|

Daniel on the Moon

Member Posts: 354

From: Bronxville, NY

Registered: Jun 2015

|

posted 10-05-2017 04:17 PM

posted 10-05-2017 04:17 PM

Very perceptive questions. quote:

Originally posted by MCroft04:

Were there procedures to insure that changes to flight hardware were quickly communicated to you?

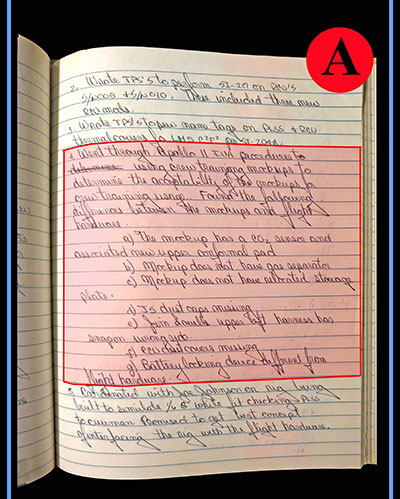

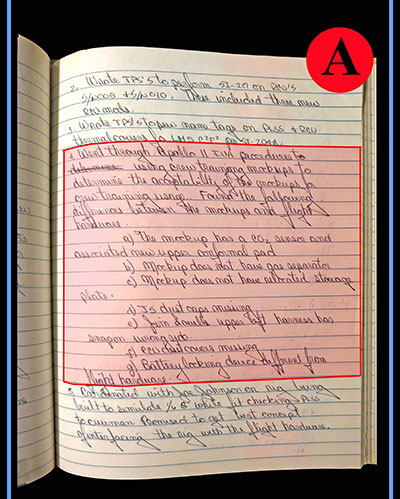

There were no formal procedures to communicate changes to me. We were dealing with a fully documented, regulated flight hardware program and a NON-documented NON-regulated training program with respect to Full Scale Mockups, Cryopacks, Airpacks, Water Cooling Packs and other training support hardware.It was, in fact, my responsibility to know what modifications were made to the flight hardware and make sure those modifications were incorporated into the training mockups. Keep in mind that I worked with the flight PLSS/OPS/RCU on a daily basis so I attended meetings that involved flight hardware changes and procedures. All memos both internally at KSC and from our Hamilton Standard home office in Windsor Locks, Conn. were either directed to me or cc'd to me so it was a matter of being "diligently dedicated" while accomplishing my responsibility. I'll present to you a few examples pertaining to maintaining identical flight and mockup configurations. Graphic (A) below represents a page in one of my Apollo 11 notebooks. The pink highlighted section reads as follows: Went through Apollo 11 EVA procedures using crew training mockups to determine the acceptability of the mockups for crew training usage. Found the following differences between the mockups and flight hardware. - The mockup has a CO2 sensor and associated new upper conformal pad.

- Mockup does not have gas separator

- Mockup does not have relocated stowage plate.

- J5 dust caps missing.

- Jim lovell's upper left harness has snap on wrong side.

- RCU dust covers missing.

- Battery locking device different from flight hardware.

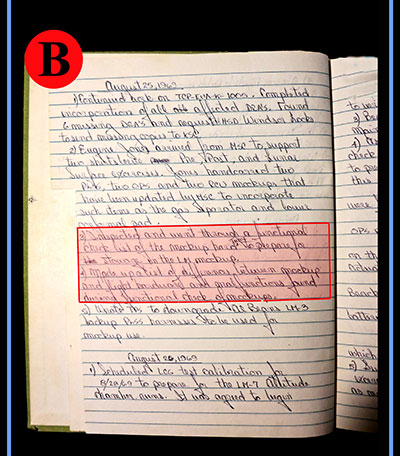

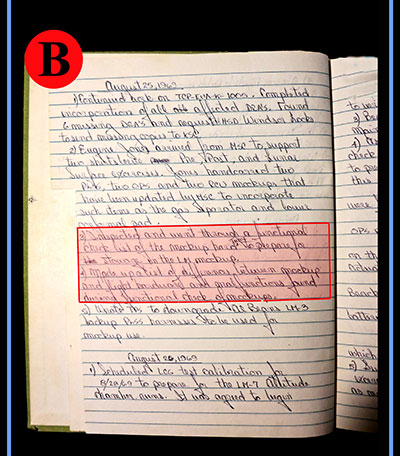

Graphic (B) below represents a page from one of my Apollo 12 notebooks. The pink highlighted section reads as follows: - I inspected and went through a functional check list of the mockup hardware to prepare for stowage in the LM mockup.

- Made up a list of differences between mockup and flight hardware and malfunctions found during functional check of mockups.

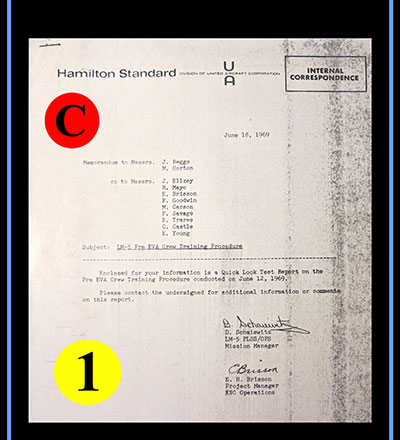

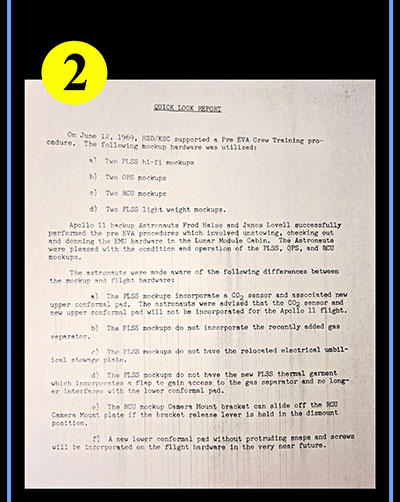

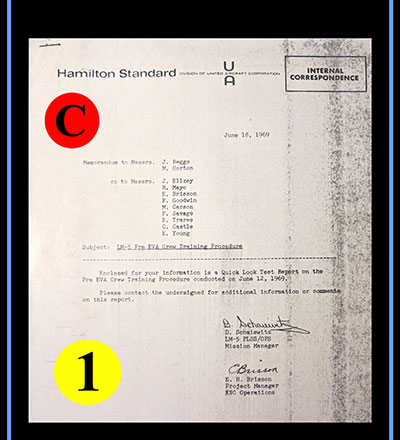

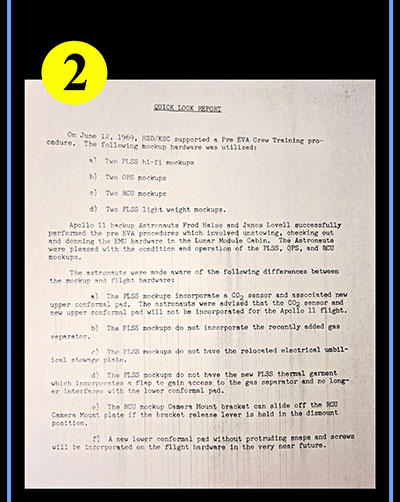

With respect to making sure Flight and Mockup hardware configurations were continually updated, I wrote "formal" QUICK LOOK REPORTS, Reference Graphic (C-1) and (C-2) below. As LM-5 PLSS/OPS Mission Manager, I wrote the below report titled: LM-5 Pre EVA Crew Training Procedure. This specific report related to a procedure on June 12, 1969.Reference Report Page (2) below. It reads as follows: On June 12, 1969, HSD/KSC supported a Pre EVA Crew Training procedure. The following mockup hardware was utilized: - Two PLSS hi-fi mockups

- Two OPS mockups

- Two RCU mockups

- Two PLSS light weight mockups

Apollo 11 backup astronauts Fred Haise and James Lovell successfully performed the pre EVA procedures which involved unstowing, checking out and donning the EMU hardware in the lunar module cabin. The astronauts were pleased with the condition and operation of the PLSS, OPS and RCU mockups.The astronauts were made aware of the following differences between the mockup and flight hardware: - The PLSS mockups incorporate a CO2 sensor and associated new upper conformal pad that will not be incorporated for the Apollo 11 flight.

- The PLSS mockups do not incorporate the recently added gas separator.

- The PLSS mockups do not have the relocated electrical umbilical stowage plate.

- The PLSS mockups do not have the new PLSS thermal garment which incorporates a flap to gain access to the gas separator and no longer interfaces with the lower conformal pad.

- The RCU mockup Camera Mount bracket can slide off the RCU Camera Mount plate if the bracket release lever is held in the dismount position.

- A new lower conformal pad without protruding snaps and screws will be incorporated on the flight hardware in the very near future.

quote:

Did you ever receive feedback from an astronaut that their final flight hardware (when they reached the moon) was different from the training hardware?

"NO" and proud to give you that answer!

|

Daniel on the Moon

Member Posts: 354

From: Bronxville, NY

Registered: Jun 2015

|

posted 10-11-2017 01:42 PM

posted 10-11-2017 01:42 PM

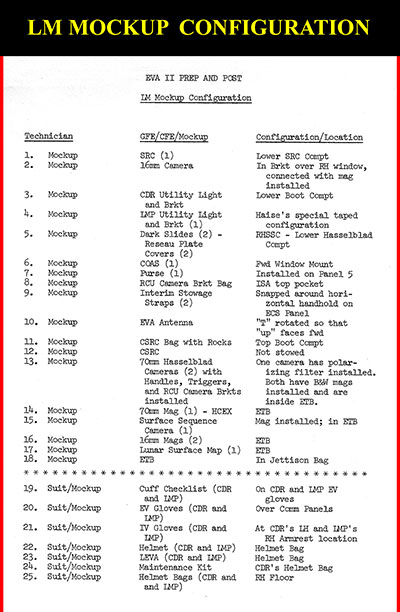

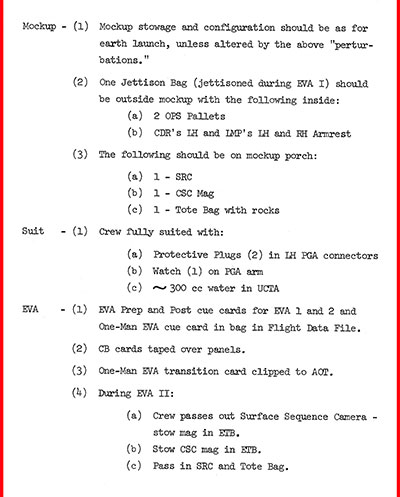

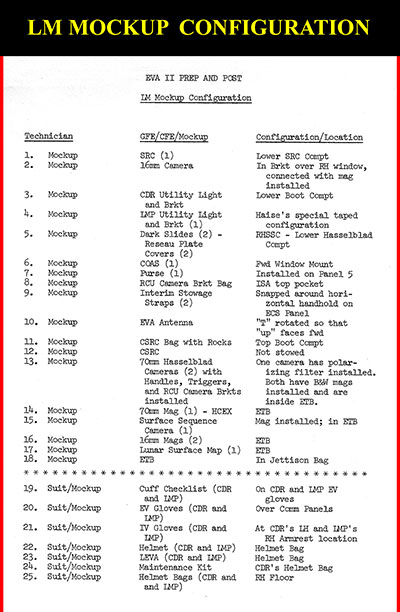

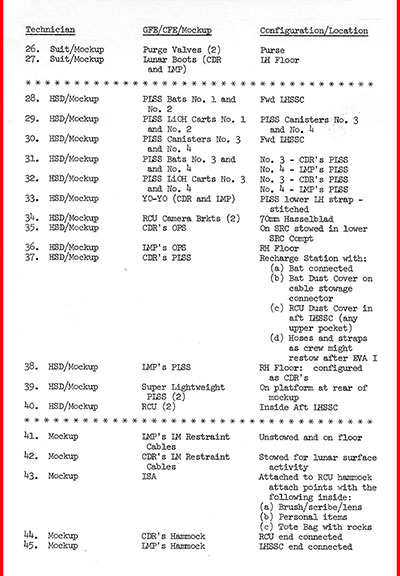

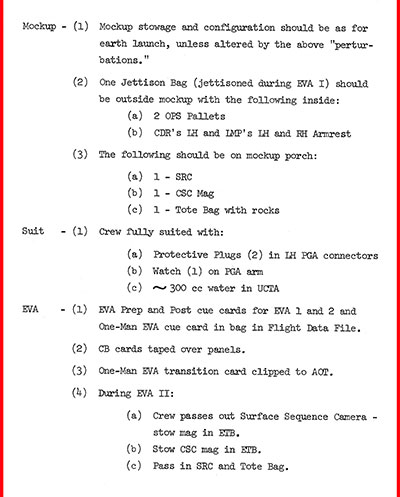

In my most recent post, I referenced the use of PLSS/OPS full scale mockups in a Quick Look Report memo that I wrote discussing the results of a LM-5 Pre EVA crew training procedure. This procedure was conducted inside the LM mockup.Before every pre- or post-training exercise inside the mockup LM, the LM had to be configured for the specific exercise. This may sound like an easy task, but remember, missions had up to three EVAs and each pre and post procedure required different LM configurations. The below three pages from a specific EVA-11 prep and post LM mockup configuration document was giving to me one to two days before the exercise. With the document in hand, I and one of my techs drove to the crew training building and along with a suit tech and CSD EVA prep and post test conductor configured the mockup as written in the referenced document. I'm sure those of you intrigued by the detailed nuances of the Apollo program will appreciate examining the below pages.

|

Daniel on the Moon

Member Posts: 354

From: Bronxville, NY

Registered: Jun 2015

|

posted 10-11-2017 11:18 PM

posted 10-11-2017 11:18 PM

With cS, e-mail, messaging and social media, have you ever imagined the voice that might be associated with your contacts?I'm in the imagine column. For those of you in that column that have wondered what I would say and sound like if I met you and we carried on a conversation about my incredible Apollo Program experiences, imagine no further. You can listen to a podcast that was recorded by RR Auctions discussing my Apollo experiences as they relate to memorabilia from my collection that is included in the RR space auction that begins today. |

Daniel on the Moon

Member Posts: 354

From: Bronxville, NY

Registered: Jun 2015

|

posted 10-18-2017 12:31 PM

posted 10-18-2017 12:31 PM

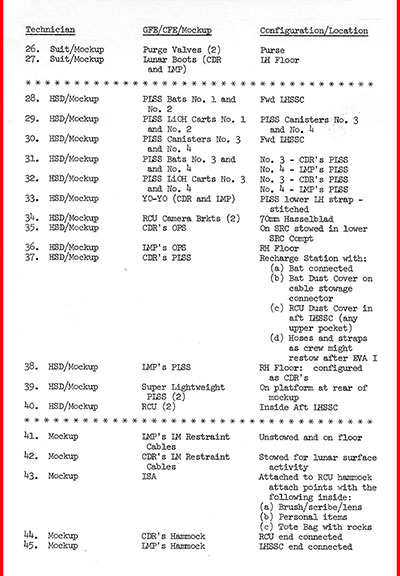

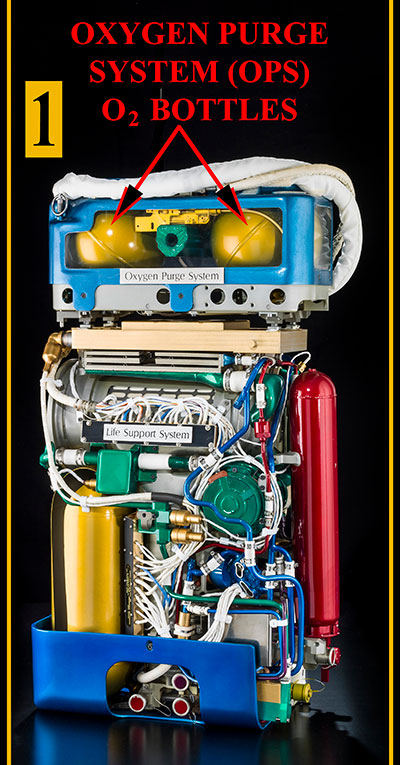

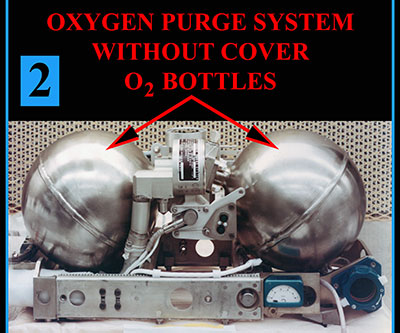

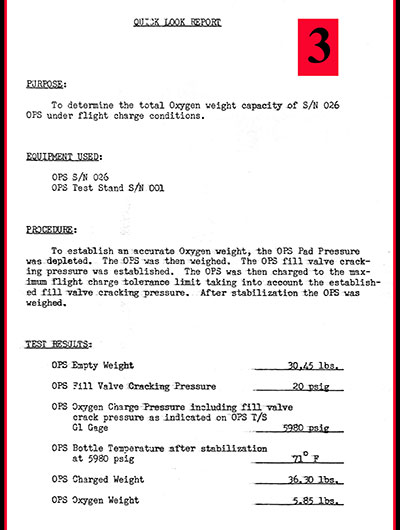

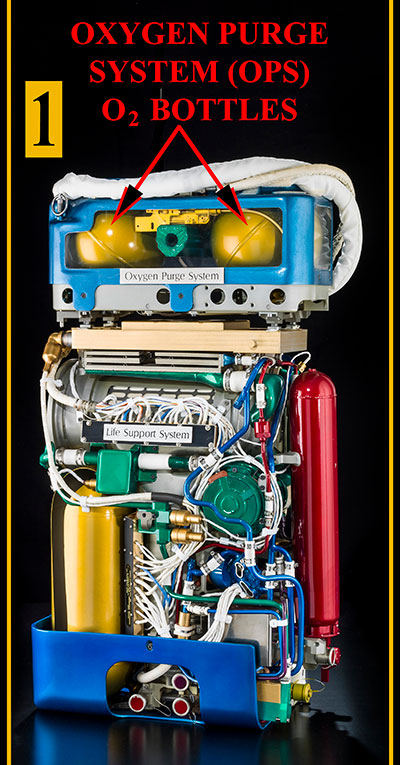

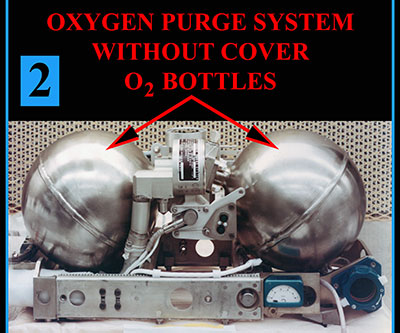

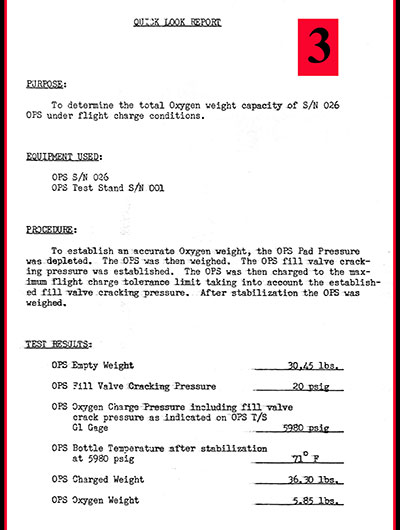

As I've stated on more than one occasion, I am the "luckiest man in the world!"Being as intimately involved in the Apollo program as I was, there were so, so many fascinating details that I thoroughly enjoy sharing with cS members. I hope that my posts continue to be as interesting to you as they are to me. Following is a great example of a "detail" that when you think about it, you might say to yourself, "Wow, another Apollo fact that I never considered!" Here it is: Before each and every Apollo mission an exact vehicle earth liftoff and lunar liftoff weight had to be established for obvious reasons. Going through my boxes and boxes of Apollo paperwork that I saved (I saved every document that related to my Apollo experience), I came across one of the many interesting memos that I wrote. In this case the attached "Quick Look Report" (Graphic 3 below) describing a test procedure and test results to determine the weight of the Oxygen in the Oxygen Purge System bottles (Graphics 2 and 3 below). When you think about it, adding the weight of an intangible object to include in the total weight of the spacecraft is not something, quite honestly, I would have considered! The referenced Quick Look Report (Graphic 3) is self explanatory. The results of the report establishing the weight of the Oxygen in the OPS bottles at 5.85 lbs is to me fascinating!

|

Kite

Member Posts: 1163

From: Northampton UK

Registered: Nov 2009

|

posted 10-18-2017 04:03 PM

posted 10-18-2017 04:03 PM

Your broadcast was absolutely fascinating Dan. You sound as clear and precise as you write. We are so lucky to have you on collectSPACE to recollect your amazing experience with the Apollo programme. Good luck with the auction. |

Daniel on the Moon

Member Posts: 354

From: Bronxville, NY

Registered: Jun 2015

|

posted 10-18-2017 05:39 PM

posted 10-18-2017 05:39 PM

Thank you for your kind and motivating words. |

Daniel on the Moon

Member Posts: 354

From: Bronxville, NY

Registered: Jun 2015

|

posted 10-20-2017 07:55 PM

posted 10-20-2017 07:55 PM

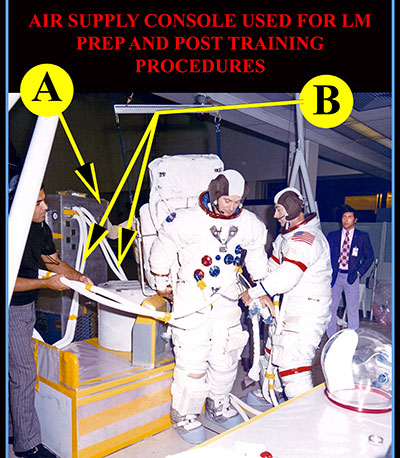

When I previously discussed the use of the PLSS/OPS full scale Mmckups, I related how they were used inside the crew training LM. Performing LM prep and Post procedures inside the LM was the ideal scenario, however, the downside of working in the enclosed confines of the LM was that critical test conductor and tech observation was limited.

We therefore conducted the majority of LM prep and post procedures in an open area of the crew training building. As I discussed in a previous post, a LM engine cover and step to simulate the space in the LM used to don and doff the PLSS/OPS was fabricated.You've seen many photos depicting LM pre and post procedures in the open space of the crew training building so that's nothing new. What is new is a reminder that the PLSS/OPS full scale mockups are one of four PLSS/OPS training configurations that were required to practice both lunar surface and LM procedures vs one flight PLSS/OPS.

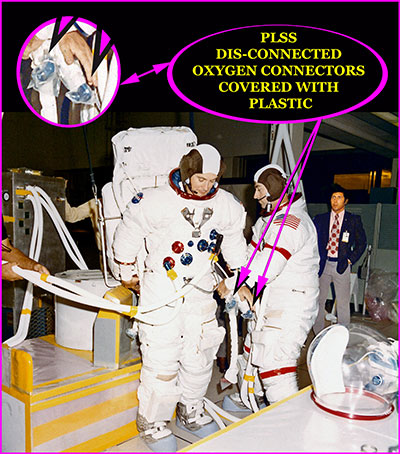

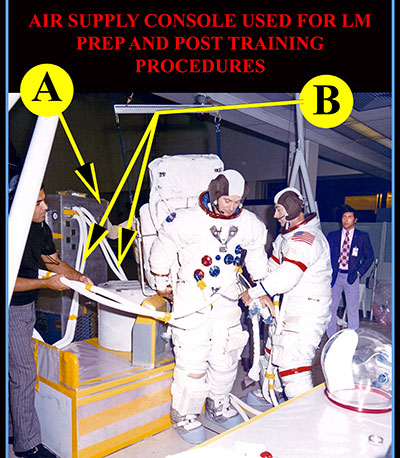

Each PLSS/OPS training configuration required a source of breathable air, cooling and suit pressurization. When completely suited during LM prep and post procedures using the PLSS/OPS full scale mockups, breathable air was provided by using the air supply from the Air Console Unit (A) in the below photo. With the mockup PLSS oxygen inlet and outlet hoses disconnected, hanging free, the air console inlet and outlet air supply hoses (B) were connected to the suit inlet and outlet oxygen connectors and provided air to the suited crewman. As you can see in the photo, there were two sets of inlet and outlet hoses for both the CDR and LMP.  |

Daniel on the Moon

Member Posts: 354

From: Bronxville, NY

Registered: Jun 2015

|

posted 10-22-2017 12:28 AM

posted 10-22-2017 12:28 AM

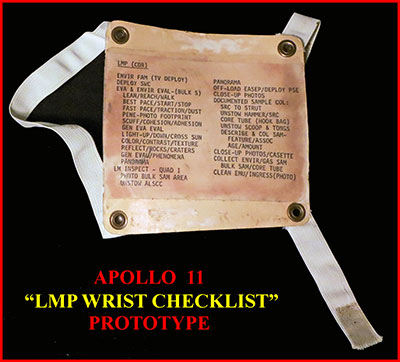

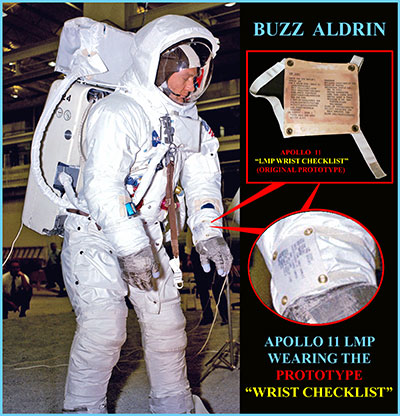

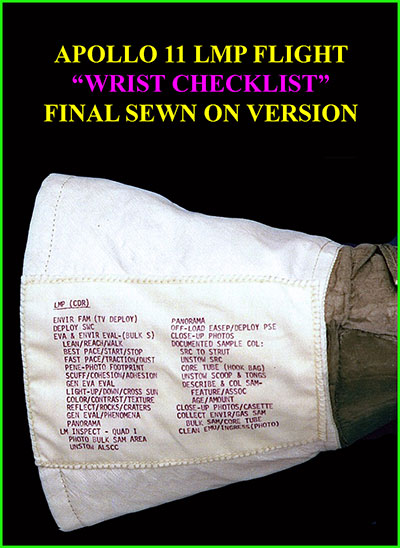

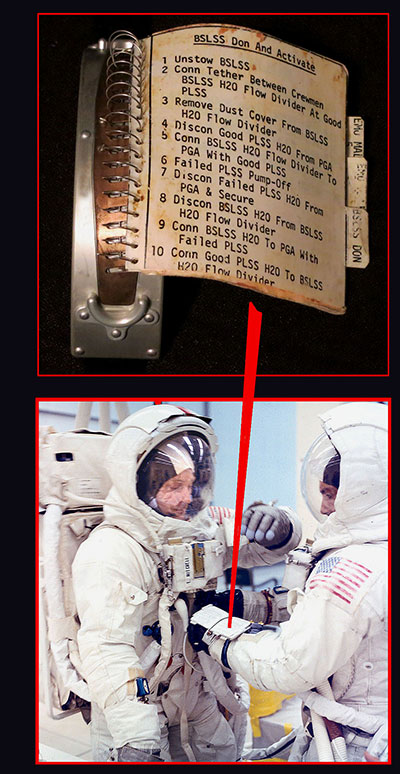

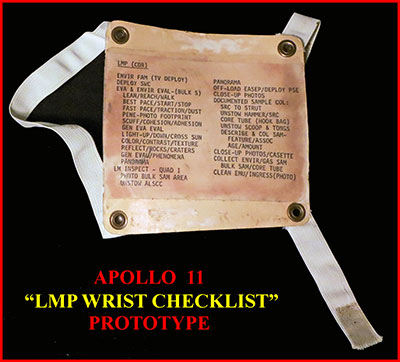

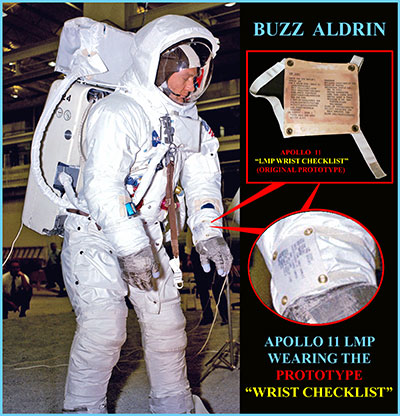

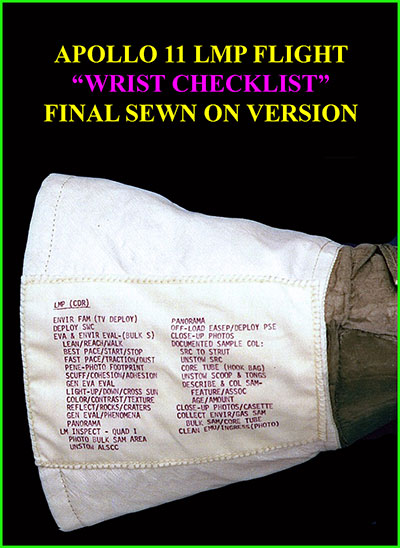

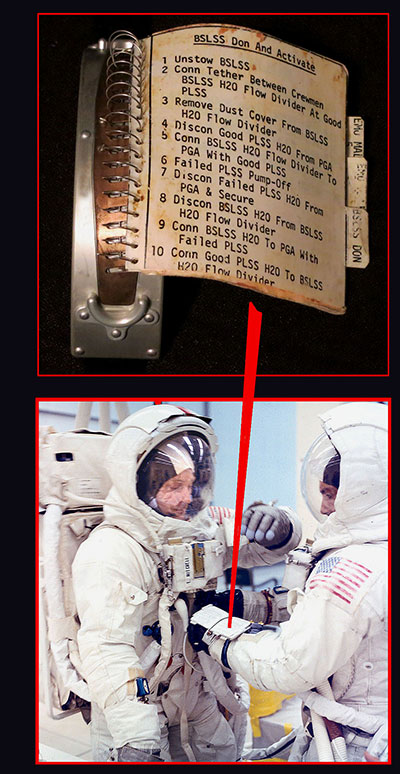

During one of the early Apollo 11 EVA Crew Training Exercises, the idea of a "wrist checklist" was initiated by astronaut Neil Armstrong when he suggested that there should be a written task reminder or as we might refer to today as an "action item list." The task reminder evolved into a checklist that could be secured to the astronaut's EVA glove and was logically named a "wrist checklist."Since both Armstrong as CDR and Aldrin as LMP had different lunar surface tasks to accomplish, there were two individualized checklists. The photo below represents the first attempt at creating a "wrist checklist." The below prototype wrist checklist reflects the tasks performed by Aldrin as LMP. Note that tasks in parentheses, i.e. (TV DEPLOY), etc. are tasks to be accomplished by Armstrong as CDR. These tasks, in parentheses, are just a reminder for the LMP. The CDR checklist also had important LMP tasks in parentheses.  Following is a photo of LMP Aldrin wearing the prototype wrist checklist during an EVA crew training exercise:  After noticing that the wrist checklists did not remain in the installed position, i.e. they rotated on the wrist, it was decided to permanently sew the words of the checklist to the astronaut gloves as seen in the below photo. The words fit in the designated area of the glove and could be easily read by the crew.  Subsequent Apollo missions involved considerably more tasks and a new concept had to be created to include entire mission tasks. The below photo depicts the final wrist checklist concept used that included a spiral binder with plastic pages that were turned by the astronaut as he proceeded through his tasks.  |

Tykeanaut

Member Posts: 2280

From: Worcestershire, England, UK.

Registered: Apr 2008

|

posted 10-22-2017 09:12 AM

posted 10-22-2017 09:12 AM

Great podcast, erudite and clear. You must write a book Dan? |

Daniel on the Moon

Member Posts: 354

From: Bronxville, NY

Registered: Jun 2015

|

posted 10-22-2017 10:37 AM

posted 10-22-2017 10:37 AM

Thank you for your interest. Let's toast a "Real Ale" to your suggestion! |

Kite

Member Posts: 1163

From: Northampton UK

Registered: Nov 2009

|

posted 10-22-2017 11:00 AM

posted 10-22-2017 11:00 AM

I say "CHEERS" to that! |

Daniel on the Moon

Member Posts: 354

From: Bronxville, NY

Registered: Jun 2015

|

posted 10-22-2017 12:44 PM

posted 10-22-2017 12:44 PM

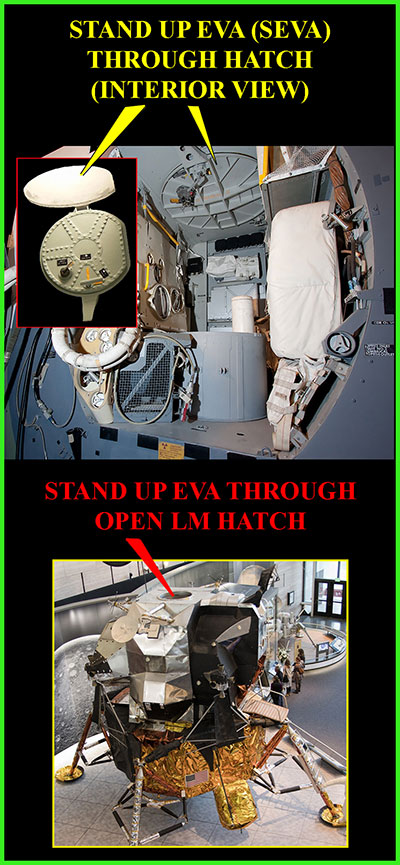

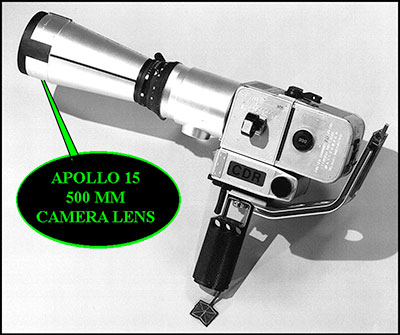

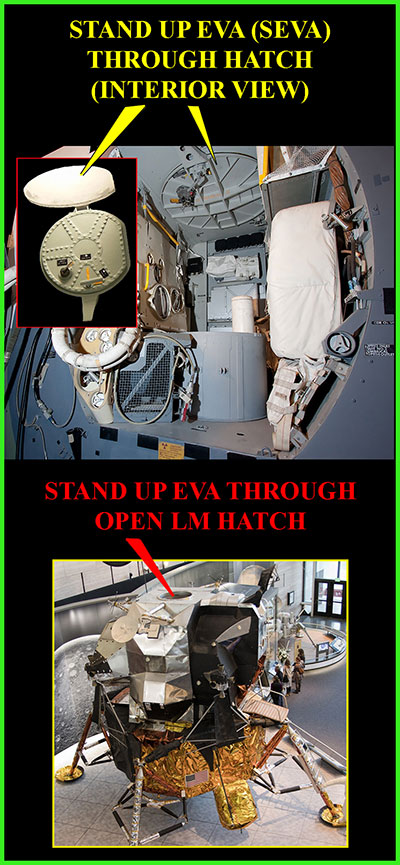

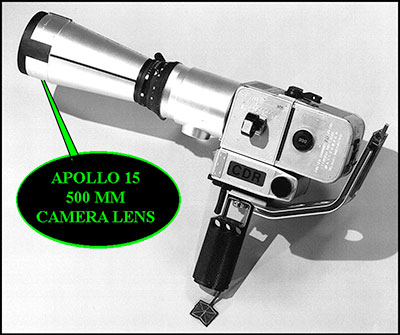

One of the skills that Apollo 15 CDR Dave Scott learned during his geology training was the need to gain a visual perspective of the landing site that he was about to explore.With this in mind, he requested mission planners to schedule a Stand-Up EVA (SEVA) a couple of hours after touchdown in which he would stand on the ascent engine cover, poke his helmeted head through LM's top hatch and photograph his surroundings.  Practicing the SEVA in the LM mockup was easier said than done. Scott insisted on rehearsing the SEVA procedure fully suited and pressurized to confirm that he was able to "poke" his head through the LM overhead hatch and move a 500 MM camera lens attached to the Hasselblad through the hatch, successfully taking the desired photos.  It was an interesting day as we had to reroute the air supply hose through the overhead hatch to Scott's suit inlet oxygen connector. There was Scott, his head and camera poked through the hatch and the air hose inadvertently getting in his way. At one point during the procedure, the hose wrapped around his helmet. I wish I had photos to show you. Bottom line though, everyone was satisfied with the procedure. After the mission, Scott said "The SEVA was a useful experience. One of our problems at Hadley (the landing site), was that the resolution of the Lunar Orbiter photography was only 60 feet, so they couldn't prepare a detailed map. The maps we had were best guesses and we had the radar people tell us before the flight that there were boulder fields at the landing site so a rational reason for the stand-up EVA was to look and see if we could drive the rover, because if there were boulder fields down there, and nobody could prove there were no boulder fields, it changed the whole picture."

The view set his mind at ease, appearing to totally contradict his pre-flight fears. The Rover "trafficability," as Scott put it, would be excellent. Another reason for the SEVA was that people in the world of geology supported the SEVA, and said yes, that will be useful geologically getting photos from the vantage point of the hatch at the highest point of the LM, especially using, for the first time, a 500mm camera lens and having a stable platform by resting the camera on the flat circumference around the open hatch. Why was there no Stand Up EVA (SEVA) on Apollo 16 or 17? The timing of Apollo 15's landing meant that Scott and Irwin had already been awake for 11 hours. It wouldn't have been wise to then send them out on a full EVA but it would have also been unrealistic to expect them to go to sleep knowing the moon was just outside the window!

The stand-up EVA filled the gap, while also allowing Scott to get a good idea of the landing site's geography in preparation for driving the lunar rover. Both Apollo 16 and Apollo 17 were scheduled such that the astronauts would depart on their first EVA soon after landing. And the Apollo 17 moon walkers did just that. Apollo 16 astronauts would have as well, but their landing was delayed by six hours as they worked out a problem with the command module's engine control system. Young and Duke landed having been awake for 13 hours but having not planned for a stand-up EVA, they started their first outing the next day. |

SaturnV

Member Posts: 24

From: Fowler, Ohio, USA

Registered: Sep 2013

|

posted 11-30-2017 06:17 PM

posted 11-30-2017 06:17 PM

Dan, Oh my goodness, what a treasure chest of information you have! How wonderful for us that you found this forum and have taken the time to share your experiences. Several posts ago you detailed the EMU design. Are you aware if the astronauts ever had to utilize it for any suit repairs like scuffing or perhaps O-ring lubrication? |

oly

Member Posts: 1484

From: Perth, Western Australia

Registered: Apr 2015

|

posted 11-30-2017 09:29 PM

posted 11-30-2017 09:29 PM

Dan, Somehow I missed your post on the Apollo 15 SEVA. Thank you for posting the information. I was aware that the geologists wanted the SEAV but had not thought that they also checked the terrain for the Lunar Rover work. It makes a lot of sense. |

Daniel on the Moon

Member Posts: 354

From: Bronxville, NY

Registered: Jun 2015

|

posted 12-01-2017 12:19 PM

posted 12-01-2017 12:19 PM

I personally am not aware of crewman using the EMU Maintenance Kit however, it is possible that it may have been used with its use not being significant and documented (in communications) but not being included in post mission reports. |

Daniel on the Moon

Member Posts: 354

From: Bronxville, NY

Registered: Jun 2015

|

posted 01-01-2018 09:27 PM

posted 01-01-2018 09:27 PM

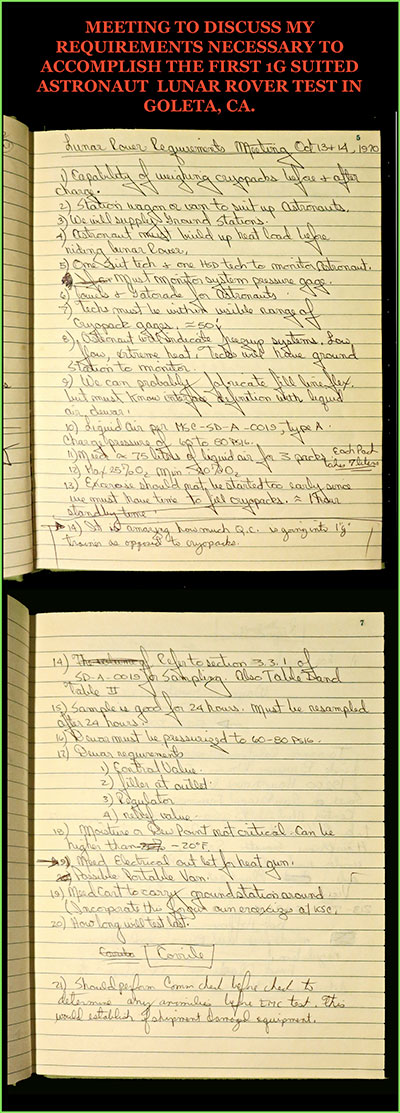

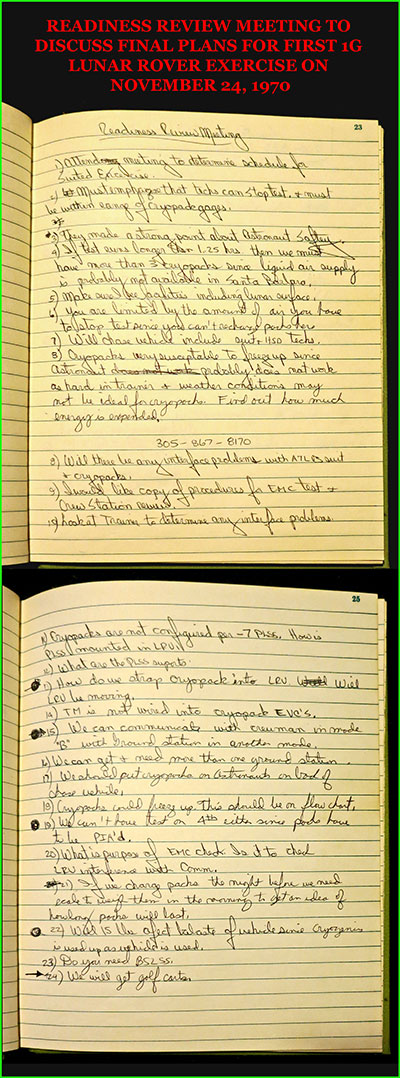

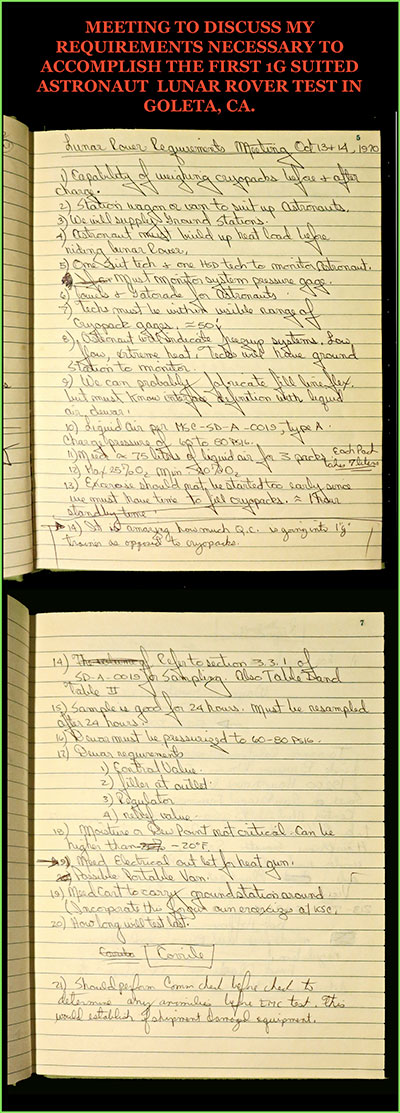

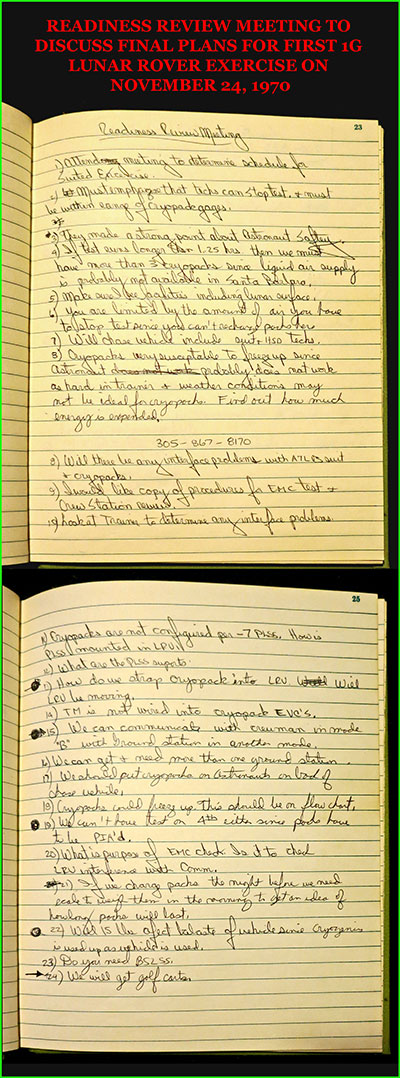

Reviewing my KSC Log Books, I have, on many occasions, found experiences that I consider "highlights" of my KSC "Personal Apollo Experience."

One such highlight involved the first test of the 1G Lunar Rover with Apollo 15 astronauts Scott and Irwin in the city of Goleta, Ca. at the General Motors Defense Research Laboratories.GM was a subcontractor to Boeing, the Lunar Rover prime contractor. Many people remember two things about the Apollo program, Neil Armstrong’s first step on the moon and the astronauts riding the Lunar Rover on the moon, myself included. On or about October 1st, 1970, I was assigned the task of coordinating the suited portion of the first 1G Lunar Rover Training vehicle test with Apollo 15 astronauts Scott and Irwin in California scheduled for November 24, 1970.

Rather than copying my Log Book notes I felt it might be more interesting to those of you that follow my posts for me to include my actual Log Book pages (see below) relating to my effort to coordinate the 1G Lunar Rover Test with the Apollo 15 Prime crew.

For those of you that have questions about the substance and/or meaning of my Log Book notes, please don't hesitate to ask.

|

em8g16

Member Posts: 21

From: Spain

Registered: Dec 2017

|

posted 01-05-2018 11:43 AM

posted 01-05-2018 11:43 AM

I'm new to this forum and collecting in general. I am also studying aerospace engineering at university. I have read through the entire thread and it has been wonderful! What an amazing story, it must have been a dream to live the Apollo program as close as you did! Truly inspiring. Thank you very much for sharing this, it has been incredible to read through it. |

Daniel on the Moon

Member Posts: 354

From: Bronxville, NY

Registered: Jun 2015

|

posted 01-05-2018 12:36 PM

posted 01-05-2018 12:36 PM

One of my goals in life is to inspire the youth of the world to pursue a career in aerospace. I'm delighted to know that my story has accomplished that objective.Good luck with your studies and your future contributions to the advancement of aerospace technology and unlocking "secrets of our universe". |

mikepf

Member Posts: 448

From: San Jose, California, USA

Registered: Mar 2002

|

posted 01-05-2018 03:12 PM

posted 01-05-2018 03:12 PM

Once again, I don't have a specific comment or question, but I continue to find these posts fascinating. I figured I should just check in so you don't think your posts are not being appreciated. Please keep them coming. Who knows, maybe I'll actually think up of a good question to ask. Best wishes for 2018! |

MCroft04

Member Posts: 1861

From: Smithfield, Me, USA

Registered: Mar 2005

|

posted 01-05-2018 06:48 PM

posted 01-05-2018 06:48 PM

Dan, I'm interested in how you came up with this list of items. It appears that a lot of pre-planning occurred; if you fail to plan then plan on failing. How many people were involved in the planning for this exercise? How early did you begin the planning (prior to the exercise)? Did you use a process that lead you to identifying all the steps necessary to carry out the exercise? Or did you do most of this on your own? |

Rocketman!

unregistered

|

posted 01-05-2018 08:39 PM

posted 01-05-2018 08:39 PM

For what it's worth, I find viewing your actual Log Book pages very interesting. Much more engaging than if they were transcribed, in my opinion.Would you mind elaborating on (the first) comment number 14 from the Oct. 13-14, 1970 meeting? It is amazing how much Q.C. is going into 1"g" trainer as opposed to cryopacks. |

em8g16

Member Posts: 21

From: Spain

Registered: Dec 2017

|

posted 01-06-2018 04:30 AM

posted 01-06-2018 04:30 AM

quote:

Originally posted by Daniel on the Moon:

Good luck with your studies and your future contributions...

Thank you very much Daniel you have indeed inspired me. I really like how you managed so much at such a young age by volunteering and working hard! Your life is like a dream come true to me. |

Daniel on the Moon

Member Posts: 354

From: Bronxville, NY

Registered: Jun 2015

|

posted 01-07-2018 11:42 PM

posted 01-07-2018 11:42 PM

quote:

Originally posted by MCroft04:

Dan, I'm interested in how you came up with this list of items.

The knowledge base I had to work with when coordinating the LRV 1G Apollo 15 suited astronaut mobility exercise was my experience setting up and coordinating suited EVA exercises for Apollo 11, 12, 13 and 14 at KSC without a Lunar Rover (first use of LRV -Apollo 15).There was a lot of pre-planning involved as you suggested.I would categorize the planning as addressing three major challenges and numerous sub-challenges. Major challenges were: - Identifying all equipment needed to support the exercise and determining the best way to ship from KSC to Goleta, Ca. without equipment damage.

- Identifying, coordinating and implementing the requirements of GM with respect to LRV/astronaut interface, safety requirements, length of exercise, equipment we needed that could not be shipped, etc.

- Finding a source of liquid air to fill the Cryopacks with the liquid air meeting KSC specifications for breathable air.

It might be of interest to cS readers to review my effort for one coordinated challenge involving finding a source of liquid air.After making numerous phone calls I found the Linde Division of Union Carbide in Torrance Ca. They met our KCS specs for breathable air and were also able to provide an interface connection to the Cropack liquid air tank (dewar). Linde was about a 20 minute drive to the GM test site in Goleta, Ca. I was given authorization from MSC Crew Systems Division to rent a van in Goleta to transfer the Cryopacks to Linde in Torrance for charging (liquid air fill) and back to GM in Goleta. Knowing that there was a problem with Cryopack air leakage as a function of time (discussed in past posts), I decided to fill the Cryopacks the morning of the exercise.To make a long story short, my HSD tech and myself woke up at 5AM, had coffee, drove to Torrance, waited about an hour to fill 4 cryopacks and drove back to GM arriving about 15 minutes before the start of the exercise. My plan was to arrive at GM an hour and a half before exercise start time. Why did it take me longer than planned from Torrance to Goleta? You guessed it, San Diego Freeway morning traffic! I always did my best to plan for every eventuality but in this case I admit failure. How many people were involved in planning the exercise? I personally coordinated with the MSC Crew Systems Division test conductor, MSC Apollo facilities manager the GM test conductor, GM System Safety engineer, Linde plant superintendent, Linde Quality Control engineer, ILC KSC suit engineer and others. |

Daniel on the Moon

Member Posts: 354

From: Bronxville, NY

Registered: Jun 2015

|

posted 01-08-2018 12:04 AM

posted 01-08-2018 12:04 AM

quote:

Originally posted by Rocketman!:

Would you mind elaborating on (the first) comment number 14 from the Oct. 13-14, 1970 meeting? It is amazing how much Q.C. is going into 1"g" trainer as opposed to cryopacks.

In a previous posts I discussed KSC flight hardware QC vs training hardware QC. The bottom line was that with flight hardware, all handling and testing was documented with engineering and quality control personnel oversight. With the training EVA equipment that I was responsible for, there was very little oversight and minimal documentation. GM QC treated both LRV flight hardware and LRV 1G training hardware on an equal basis. As such, I had to write and implement cryo-pack tests with QC documentation before shipping hardware to Ca. |

carmelo

Member Posts: 1109

From: Messina, Sicilia, Italia

Registered: Jun 2004

|

posted 01-08-2018 07:57 PM

posted 01-08-2018 07:57 PM

Dan you knew John Young, you have memories on him? |

Daniel on the Moon

Member Posts: 354

From: Bronxville, NY

Registered: Jun 2015

|

posted 01-09-2018 02:39 PM

posted 01-09-2018 02:39 PM

When working with astronaut Young, he focused on the job at hand (crew training activities). John was serious, with little or no "small talk." |

ELinder

Member Posts: 21

From: Cleveland, OH

Registered: Sep 2010

|

posted 02-02-2018 02:57 PM

posted 02-02-2018 02:57 PM

This is a fascinating thread! I was looking through the NASA Spaceflight website and found a link to the NASA U.S. Spacesuit Knowledge Capture Program. I'm assuming people who liked this thread would also be interested in the info there. I watched one presentation so far and it was extremely informative. |

Daniel on the Moon

Member Posts: 354

From: Bronxville, NY

Registered: Jun 2015

|

posted 03-03-2018 10:17 PM

posted 03-03-2018 10:17 PM

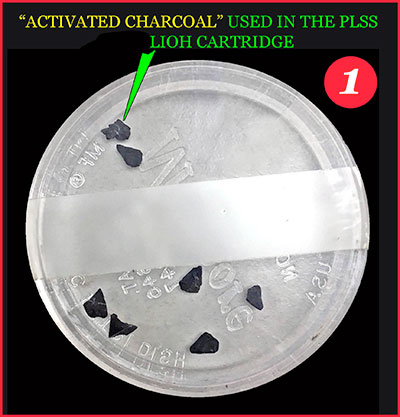

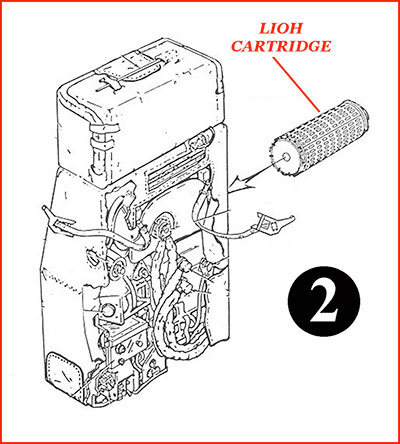

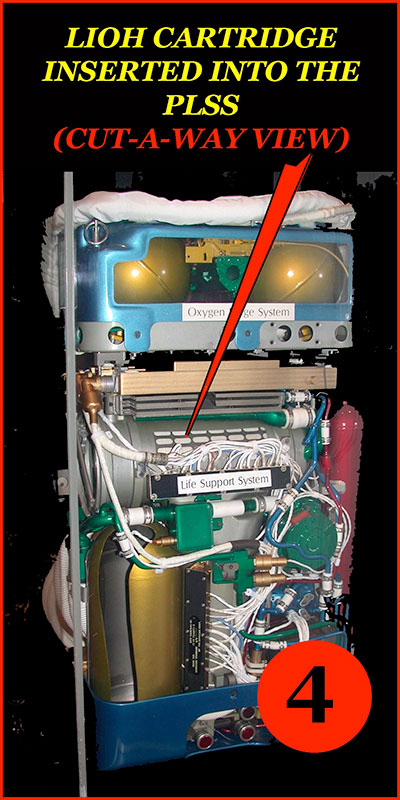

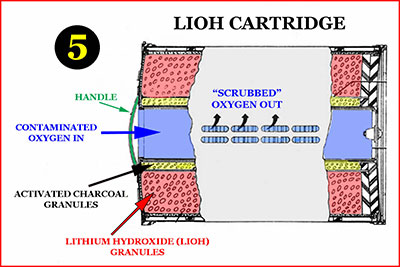

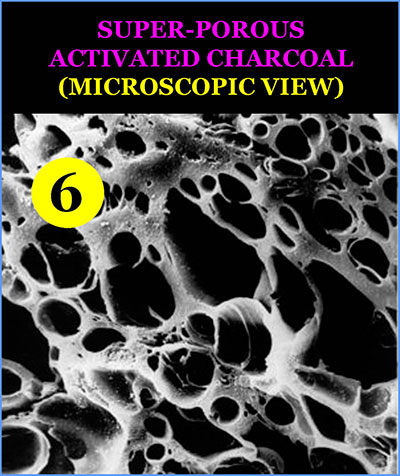

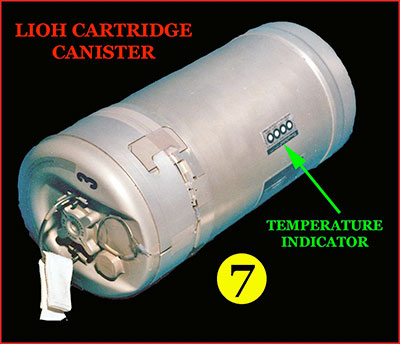

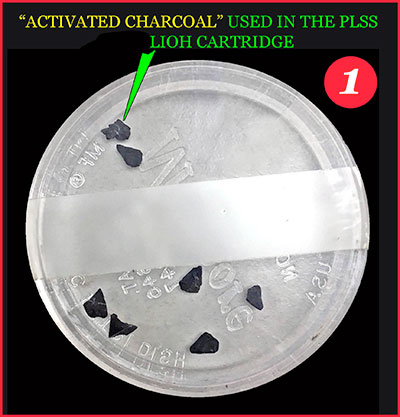

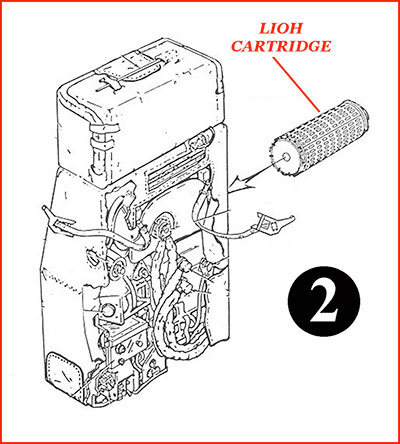

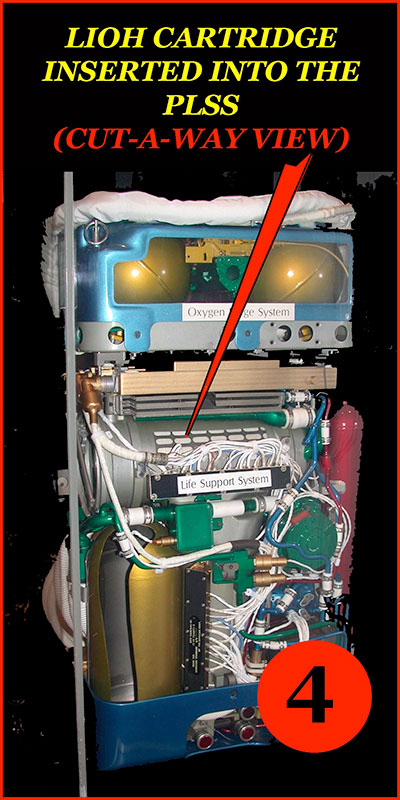

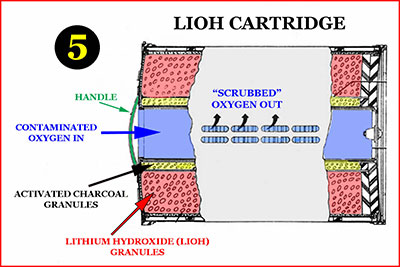

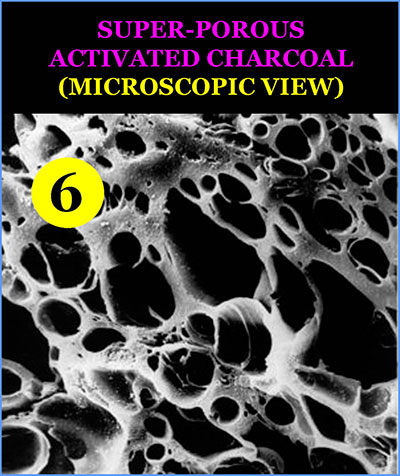

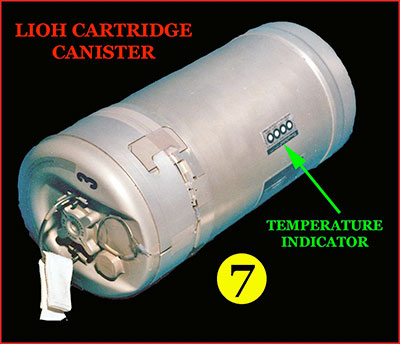

The specimens in the plastic container (Photo #1) are pieces of activated charcoal that were used in the PLSS contaminant control cartridge also known as the LIOH (lithium hydroxide) and charcoal cartridge. For the purpose of this writing, I will shorten the name LIOH and charcoal cartridge to the "LIOH cartridge." The configuration of the LIOH cartridge is depicted in Figure #2 below as a cylindrical component of the PLSS labeled "LIOH cartridge."  In Photo #3 you can see an actual LIOH cartridge being inserted or being removed from its location inside the astronaut Portable Life Support System (PLSS).  Looking at Photo #4, we see the LIOH cartridge cut-a-way view inserted inside the PLSS.  The LIOH cartridge has the following three basic functions: 1) Remove the astronaut's exhaled carbon dioxide from the oxygen being circulated through the space suit ventilation system so that the cxygen can be re-circulated as breathable oxygen. This is accomplished by passing the contaminated cxygen containing the exhaled CO2 (carbon dioxide) through a "bed" of lithium hydroxide (LIOH) granules that removes the CO2 by chemically reacting with the LIOH to form non toxic lithium carbonate allowing the CO2 "scrubbed" oxygen to be re-circulated through the astronaut ventilation breathing circuit (Reference Figure #5). 2) Remove foreign particles such as dust particles using a peripheral felt like Filter from the easily "kicked up" loosely packed Lunar soil during EVA. 3) Remove trace contaminant gases such astronaut body odor and other metabolic by-product contaminants as the circulated oxygen in the PLSS space suit ventilation circuit passes through the suit adjacent to the astronaut's body. This is accomplished by passing the contaminated oxygen over activated charcoal granules (Figure #5) identical to the granules in the plastic dish (Photo #1).  Let's take a closer look at the Activated charcoal granules (Photo #1). Activated charcoal starts life as ordinary, less absorbent charcoal, but when it is treated with steam at exceptionally high temperatures (beyond the temperature of a domestic oven) it becomes super-porous. The highly controlled steam heating process results in active charcoal that has millions of microscopic holes, not just on the inside but across its surface as well (Photo #6).  One gram of activated charcoal has a surface area of about 500 square meters. This is twice as big as the surface area of the average US home. Surface area is important because increased surface area means that the activated charcoal can absorb more gas particles. Unpleasant odors are made up of gas particles. How does the porous charcoal capture body odor and other trace contaminants? This is a complex chemical process, but it can be compared to a vacuum cleaner. Just as a vacuum sucks up dust, activated charcoal porous granules "suck" odors from the contaminated oxygen. The odors then become attached to the charcoal pores and are trapped inside, just like the dust in the vacuum cleaner bag. The larger the surface area (porosity) the more odor capture. The Millipore Filter Corporation supplied the activated charcoal to the Garrett AiResearch Corporation who in turn fabricated the LIOH cartridge under a sub-contract to Hamilton Standard, manufacturer of the PLSS. Photo #7 below represents a canister used to hold the LIOH cartridge. The LIOH cartridge can be used in the PLSS for only one EVA. As we know, we had missions with three EVAs which meant that extra cartridges were required for each mission. The cartridges were heat sensitive . As a result, the LIOH canister (Photo #7) was designed to contain the LIOH cartridge during shipping and storage and specifically to form a temperature and humidity barrier. Temperature was monitored using the temperature indicator on the outside of the canister (Photo #7). If one or more of the four white circles on the indicator turned black, we knew that a some point in time the cartridge may have been exposed to temperatures above 110 degrees and damaged, i.e. the LIOH granules possibly absorbed moisture that degraded the amount of CO2 absorption capability.  The resulting damage to a cartridge that had been exposed to out of specification temperatures resulted in a requirement to hand carry the cartridges in the passenger section of a plane so that the location and status of the cartridge could be documented and verified by the individual courier at any point during transport from one location to another. About a week before the Apollo 11 launch, we noticed that one of the LIOH cartridges assigned to the Apollo 11 PLSSs had been exposed to an out of spec high temperature. I hand carried the cartridge from KSC to Hamilton Standard headquarters in Windsor Locks, Connecticut allowing engineers to inspect and test the cartridge to determine if this was an isolated case. I was in the laboratory and witnessed the inspection and testing of the cartridge in question. After the cartridge was disassembled and tested, it was determined that the cartridge had, in fact, been exposed to out of specification high temperature. It was never determined when and where the LIOH cartridge had been exposed to the out of spec high temp. Fortunately, we had backup cartridges at KSC and one of them was assigned to replace the damaged cartridge. |

MCroft04

Member Posts: 1861

From: Smithfield, Me, USA

Registered: Mar 2005

|

posted 03-04-2018 07:57 AM

posted 03-04-2018 07:57 AM

Thanks for a wonderful post Dan! Regarding the second reason for the canisters (to remove foreign particles — such as lunar soil), I assume the filtering system was a closed loop. So I'm surprised that foreign particles were able to get into the system. For those missions with multiple EVAs, I assume that the replaced canisters were discarded onto the lunar surface with other gear that was no longer needed prior to departing the moon. |

Daniel on the Moon

Member Posts: 354

From: Bronxville, NY

Registered: Jun 2015

|

posted 03-04-2018 02:27 PM

posted 03-04-2018 02:27 PM

Yes, the ventilation loop was a closed loop system. However, the "closed loop" was open to a "non" filtered clean room environment in the LM during PLSS donning, doffing and LIOH cartridge replacement after EVA when the crew returned to the LM with lunar "dust" covered suits.During PLSS donning and doffing in the LM, the PLSS oxygen connectors were both connected and unconnected to the PGA. When unconnected and exposed to the un-filtered LM non clean room environment, the open connectors were exposed to possible dust particles from the "dusty" suits and and oxygen hoses. Also, the same scenario applies to replacing the LIOH cartridges between EVA's, again, exposing the PLSS ventilation interior system to lunar dust. Yes to your assumption that the replaced canisters were discarded onto the lunar surface with other gear that was no longer needed prior to departing the moon. |

Daniel on the Moon

Member Posts: 354

From: Bronxville, NY

Registered: Jun 2015

|

posted 03-04-2018 04:04 PM

posted 03-04-2018 04:04 PM

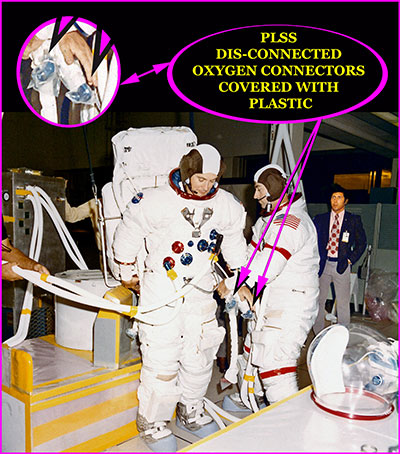

As discussed in my previous post, the only time the PLSS oxygen connectors were exposed to and not protected from a non clean room ambient environment was in the LM after a lunar surface EVA. When the PLSS oxygen connectors were not connected in a non clean room environment, the connectors were covered with plastic as I discuss below and as seen in the below photo.When completely suited during LM Prep and Post procedures using a "flight assigned" PLSS/OPS, breathable air was provided by using the air supply from the air console in the below photo. With the PLSS oxygen inlet and outlet hoses disconnected, hanging free, the air console inlet and outlet air supply hoses (below photo) were connected to the suit inlet and outlet oxygen connectors and provided air to the suited crewman. To protect the PLSS oxygen inlet and outlet hose connectors from possible contamination in the non clean room environment of the crew training building, the PLSS oxygen connectors were covered with plastic as depicted in the below photo.  |

oly

Member Posts: 1484

From: Perth, Western Australia

Registered: Apr 2015

|

posted 06-28-2018 08:24 PM

posted 06-28-2018 08:24 PM

Dan, it that you in the background of this film at the time stamp 00:03:47:18? |

Daniel on the Moon

Member Posts: 354

From: Bronxville, NY

Registered: Jun 2015

|

posted 06-30-2018 10:22 AM

posted 06-30-2018 10:22 AM

Yes, I'm checking to see if the Water Cooling Pack (that I designed) needs to be refilled with ice. Refer to my previous posts describing in detail why and how I designed and developed the Water Cooling Pack.

|