|

Author

|

Topic: Creating a Starship Super Heavy OFT1 patch

|

ImMikeD

New Member Posts: 8

From: Modesto, CA, USA

Registered: Jul 2022

|

posted 07-15-2022 06:01 PM

posted 07-15-2022 06:01 PM

Aloha! I was recommended here by the SPLC (SpaceX Patch List Collectors) mod. I am very excited to have found this community!I’m Mike D. I'm an industrial designer. I collect the mission patches for the launches I have witnessed and have been creating my own comps for future missions. So far I've seen; NOAA Michael Frielich, SN10, NROL 87 and NROL 82. I live 5 hours from Vandenberg Space Force Base. I'm sure much has been asked in previous threads so I won’t repeat too many questions til I dig further. I’m interested in making a mission patch for Super Heavy OFT1 and would love to connect here with other makers, artists or production folks who are interested in the same. Cheers all! |

ImMikeD

New Member Posts: 8

From: Modesto, CA, USA

Registered: Jul 2022

|

posted 04-08-2023 02:04 PM

posted 04-08-2023 02:04 PM

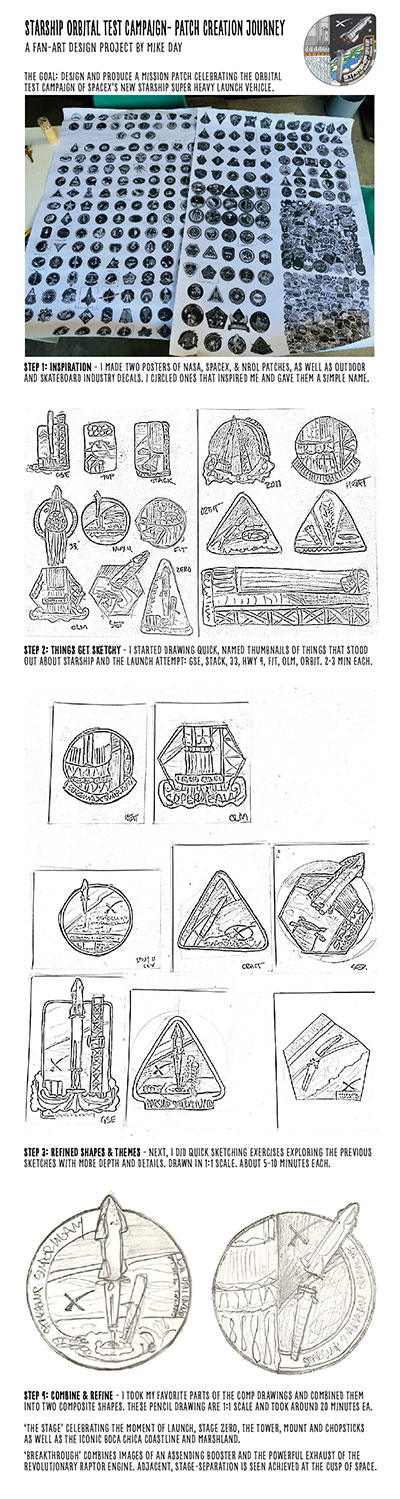

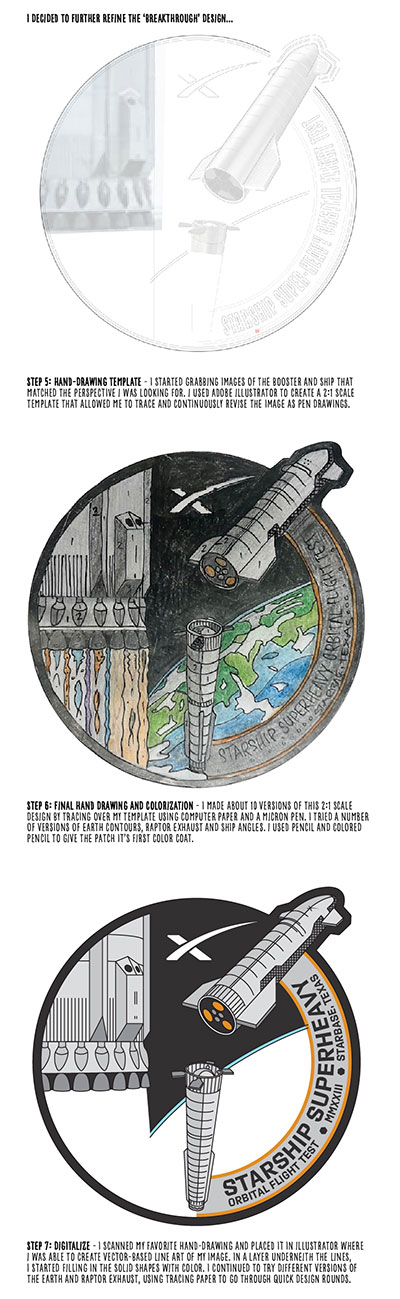

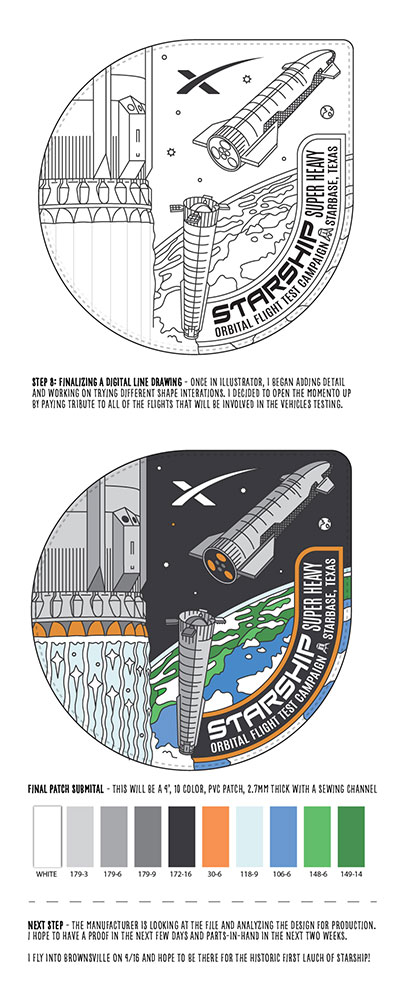

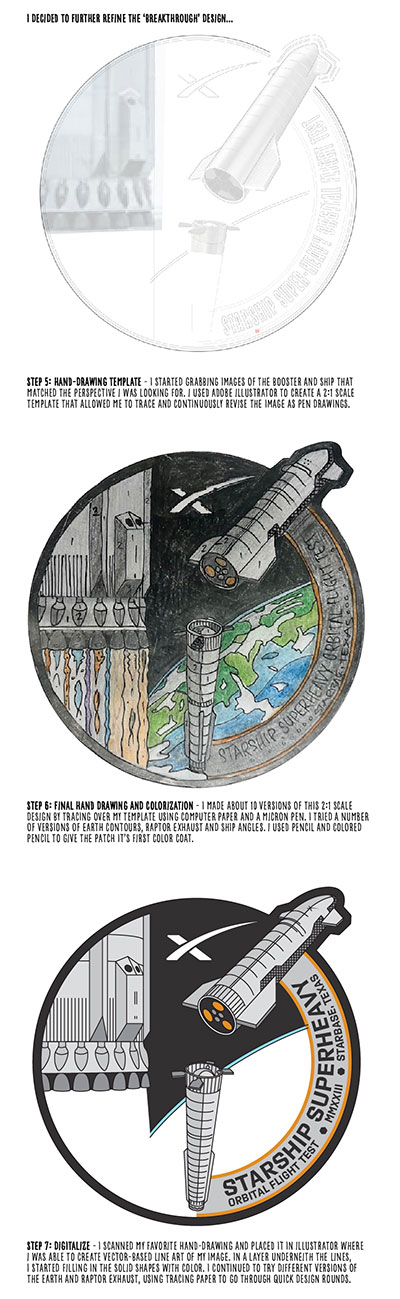

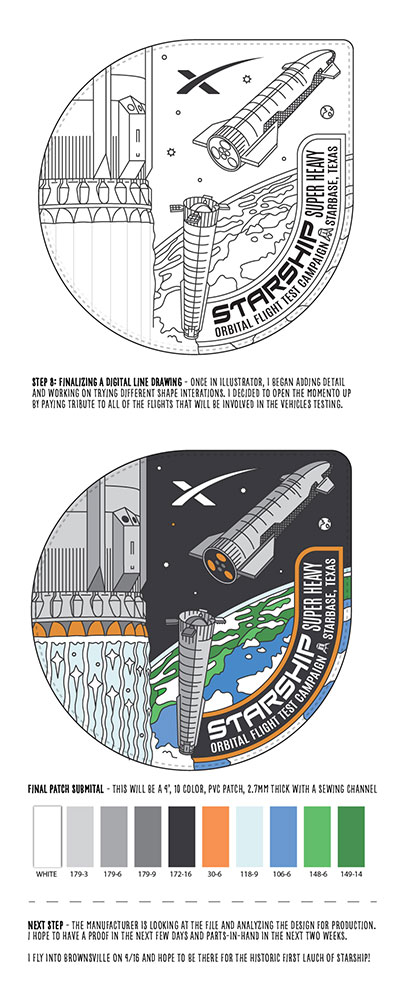

I've never designed a patch or taken one through production, but I've made a few infographics describing my journey and showing the steps. What do you think?

|

thisismills

Member Posts: 493

From: Michigan

Registered: Mar 2012

|

posted 04-08-2023 08:18 PM

posted 04-08-2023 08:18 PM

Love the design! Alot of nice deatil and the style is pleasing to the eye. Thanks for sharing with us.If you make a batch of these I would want to purchase one for my collection, I'm sure others would be interested too. Have a great trip to Starbase, very exciting to finally see the first flight of the booster, I've been really looking forward to it. |

onesmallstep

Member Posts: 1415

From: Staten Island, New York USA

Registered: Nov 2007

|

posted 04-10-2023 12:05 PM

posted 04-10-2023 12:05 PM

Welcome to cS! As you progress thru your space patch design efforts, you might look into what a respected member of this forum, Tim Gagnon (KSCartist), has done in his more than 40 years of work in the patch design field, both for NASA and nonprofit organizations/museums. You can access his work on this site via a search, and maybe even contact him directly. Good luck! |

ImMikeD

New Member Posts: 8

From: Modesto, CA, USA

Registered: Jul 2022

|

posted 04-11-2023 11:57 PM

posted 04-11-2023 11:57 PM

Thank you both for the support and kind words! It has been a really great experience having something like this to work on. I'm working on dialing-in the edits that the factory is wanting to make regarding the sewing channel and some of the details. I'll be a lot better at this the second time around now that I know the tolerances of the machines and processes. Hope to have a proof very soon. Looking forward to spending some time looking at Tim Gagnon's work. I can only imagine the extra knowledge and practice that is required to work in traditional stitchwork as well. And how much has changed since vector-based software has become the norm. Cheers! |

KSCartist

Member Posts: 3051

From: Titusville, FL

Registered: Feb 2005

|

posted 04-12-2023 07:59 PM

posted 04-12-2023 07:59 PM

From what I can see you don’t need my help, the design is beautiful! But I’m always willing to consult if you have any questions. |

Joel Katzowitz

Member Posts: 859

From: Marietta GA USA

Registered: Dec 1999

|

posted 04-13-2023 06:27 AM

posted 04-13-2023 06:27 AM

Welcome to cS Mike!I am an Industrial Designer as well and, over many years, have designed several "unofficial" patches that were worn by shuttle crews as well as a number of USPS commemorative postal cancels. I got bit by the space bug in 1989 when I designed the exhibits for the first incarnation of the U.S. Astronaut Hall of Fame in Titusville. The project was sponsored by the U.S. Space and Rocker Center and the Mercury Seven Foundation. I had the opportunity to work with several of the Mercury Astronauts during the concept phase. The experience was amazing. Feel free to reach out to me if you'd like and good luck. |

ImMikeD

New Member Posts: 8

From: Modesto, CA, USA

Registered: Jul 2022

|

posted 04-25-2023 02:01 PM

posted 04-25-2023 02:01 PM

I've gotten a production proof back from the factory and am excited to be moving forward with this patch. I learned a lot about the die-making and patch production tolerances and capabilities. I also learned a few more difficult lessons about and during communication with the foreign manufacturer. The US-based business quotes were five times the price and eight weeks for production and I found out that manufacturing took place in China anyways. Sales/estimating and getting production questions answered went easy and quickly, but their staff designers had a tendency to want to put their own touch on many of my lines which resulted in four revision requests to "put it back the way it was." These back-and-forths have been taxing! I hope to have a photo of a production sample very soon and will keep this thread updated as it occurs.  |

ImMikeD

New Member Posts: 8

From: Modesto, CA, USA

Registered: Jul 2022

|

posted 05-03-2023 11:31 AM

posted 05-03-2023 11:31 AM

I've just gotten a few photos of a production sample from the factory. The colors are a bit off but I am overall happy with the shapes and details. The lightest gray needs to be lighter and the blue exhaust and glow around Earth appears as a dull gray. I'll get to a PMS book and nail down the colors. The sample-making process took about 12 calendar days as it overlapped International Labor Day and the factory was closed for an extra long weekend.

|

rasorenson

Member Posts: 117

From: Santa Clara, CA, USA

Registered: Nov 2009

|

posted 05-03-2023 01:15 PM

posted 05-03-2023 01:15 PM

Great design! I've enjoyed creating a couple space shuttle era patches as well. Tim Gagnon was very helpful. Please let us know if/when you achieve production — you can probably easily move 500+ pieces. I'd buy one! Enjoy the process. |

thisismills

Member Posts: 493

From: Michigan

Registered: Mar 2012

|

posted 05-04-2023 07:29 AM

posted 05-04-2023 07:29 AM

Thanks for the update! The patch really looks nice and love the detail. |

J Blackburn

Member Posts: 297

From: Riner

Registered: Sep 2011

|

posted 05-05-2023 09:31 AM

posted 05-05-2023 09:31 AM

Very nice design all around. I am sure it has been frustrating at times dealing with manufacturers but it looks like your hard work is paying off and satisfying.I am curious why you chose the PVC style over embroidery? I know the Space Force uses PVC and some other agencies not associated with anything space are beginning to go PVC. SpaceX is a "modern company" and "futuristic company" at best. Myself, I am an embroidered patch guy but I am old school. Either way your design has turned out very well and I will be adding one to my collection. Congratulations on a job well done. |

ImMikeD

New Member Posts: 8

From: Modesto, CA, USA

Registered: Jul 2022

|

posted 05-05-2023 05:44 PM

posted 05-05-2023 05:44 PM

Firstly, my apologies for not directly replying to everyone's earlier comments in the thread. I was today-years-old when I learned what the four icons over the messages meant; how to see member info, send emails, edit post, and reply directly to that post. Glad I got it figured out!Thanks for the kind words and great question about choosing PVC for my patch. The answer is easy and the biproduct of the answer is why I am here at cS in a way... The short answer is that the PVC was easier for me. I draw and know Adobe Illustrator well and watched a few YouTube videos on the process of making the PVC patches which made me feel pretty comfortable with the design process. The learning curve for manufacturing was very fast. The tolerances of the die and ability of the machines are pretty well established and easily shared. I know the basics of sewing and patternmaking for fashion and costume but not a lick about embroidery, the machines, file prep, any stitch style name... I lack the ABCs of it all enough to even begin. Could be an over-simplified metaphor, but to me PVC is like drawing a coloring book with a sharp pen and then coloring it in; pretty straight forward. Traditional patch making seems more like sidewalk-chalking a mural. You have to have a bigger vision and you don't have the benefit of hard lines and easily discernible shapes, but you get gradients, textures, layers, metallic threads, and the ability to keep modifying the next piece instead of a fixed die with a slow and costly retooling. Overall, I came to cS because I was hoping to connect with other makers more than anything. It is very difficult to learn a 'trade' like this nowadays without some sort of community backbone and support. I was hoping that I could both be the backbone for someone else who wanted to turn their space/aeronautics interest into something physical and sharable like this through an example, and I was hoping as well to learn new skills along the way. I would love to learn traditional patch making methods. Any recommendations on where to start? Would I use the same basic .AI file that I've already created? I imagine that there is an entire language and shorthand that goes along with such an artform. Aloha Friday All! |

rasorenson

Member Posts: 117

From: Santa Clara, CA, USA

Registered: Nov 2009

|

posted 05-07-2023 02:35 PM

posted 05-07-2023 02:35 PM

I'm not an embroidery expert. that said, I have hand embroidered my own concept patch. As a collector, I've appreciated subtle detail machine designs as complex as direction of thread stitch. But that's still above my pay grade as a craftsperson. I do very much enjoy the beauty of real embroidery, while PVC can give you accuracy in design. Embroidered patches can have more clothing applications. I found using different manufacturers produced different appearances in thread color, type, stitching. If producing in volume, I'd certainly get samples from a few different production businesses. Enjoy! |

rasorenson

Member Posts: 117

From: Santa Clara, CA, USA

Registered: Nov 2009

|

posted 05-08-2023 02:39 PM

posted 05-08-2023 02:39 PM

... you can always make both pvc and embroidery. There are more patch collectors out there than you might think.

|

ImMikeD

New Member Posts: 8

From: Modesto, CA, USA

Registered: Jul 2022

|

posted 07-09-2023 02:32 PM

posted 07-09-2023 02:32 PM

It's taken a year from the first sketches, but I am excited to have a finished production patch commemorating the Starship Super Heavy test flights; now properly called out as Integrated Flight Test Campaign. It's was a roller coaster of a project with what felt like an easy learning curve, a difficult language barrier, and an eye-opening dive into colored PVC part production. Getting their designer to keep the lines of my original artwork and the factory to match the called-out PMS colors when making the production sample where the primary hold-ups. If I spoke Mandarin this would have been done 6 months ago!I'm happy with the production quality and the speed of delivery once the proof was accurate. I would still love to tweak a color or two and fine-tune some of the 3D components but I'm happy to step back and call the project complete. Thank you all again for the feedback and inspiration along the way. I felt like giving up many times during the process and having community support kept me working through it to the end. This patch is available right now for members at SpaceX Patch List Collectors (much love to them for grabbing half of my lot and donating their profits to charity) and I would love to be able to offer the remaining patches to domestic collectors here who were interested ($12 — includes regular USPS shipping) before I put them up on my Etsy site for sale to the general public. Email me if you are interested. I made 100 pieces. Aloha!  |