posted 04-13-2021 10:45 AM

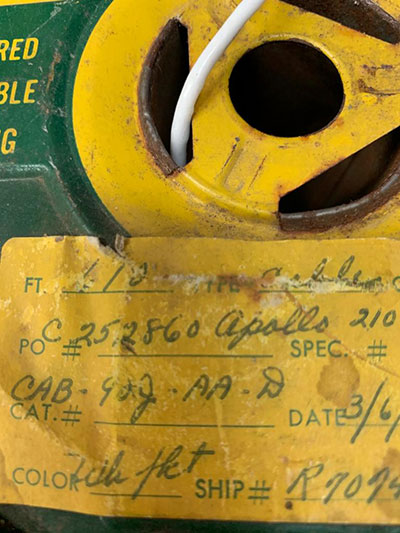

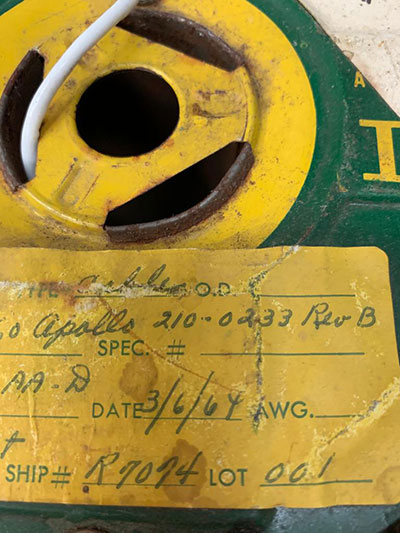

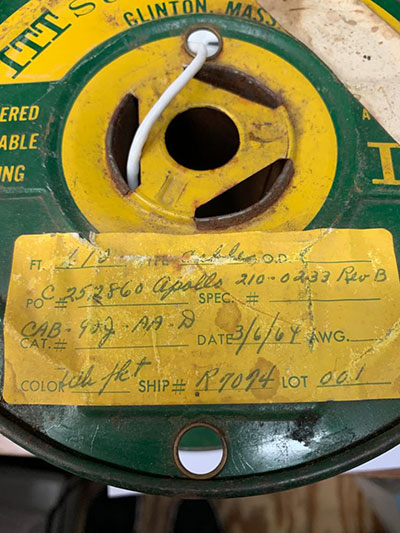

I can only offer advice from what detail I can make out in your images.The lack of identification is troubling, aircraft and aerospace wiring have had identifying marks since the use of AN and MS part numbering systems as a way to prove that the material complies with standards.

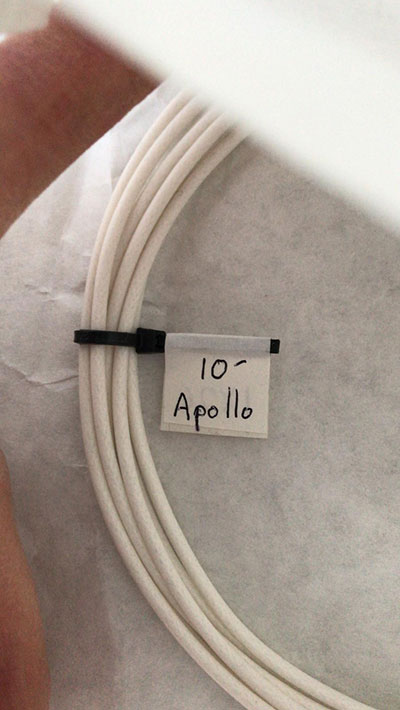

It does not look to be Kapton insulated wire.

It looks more like Teflon coated wire, which when compared to plastic coated wire, has a much thinner outer coating that reveals the texture of the underlying wire shield that can be seen in your last image.

However, I believe that Teflon coated wire did not enter use in the aerospace industry until the mid-1980s, as it was designed as a replacement material for Kapton, which was found to develop embrittlement and cracking of the insulation material when it aged. (it has been accredited to many aircraft accidents, including a suspected connection to the Swissair Flight 111 loss).

As I mentioned previously, The Lunar Module program is well known for the weight saving program, one of the areas that weight was cut was via the use of lightweight wire and small wire gauge. Following the Apollo 1 fire, additional attention was given to reducing the weight of the wiring of the module because all switches, components, and connections were hermetically sealed, and the wire weight was again reduced by making all wire routes as short as possible. Therefore, the wiring used in the LM has a red/gold appearance unless it was used in high temp areas. Even the LM cabin utility light had a gold coloured coiled power cable.

I am not sure about the command and service module wiring, perhaps someone with access to flight hardware could describe the type of wire used.

Before the introduction of Kapton and Teflon, aerospace wiring used a fabric insulator on multi-core wire that has a wax cotton appearance.

The alternative was a plastic-coated wire, however, this is not used in areas that experience extreme temps or vibrations and I suspect would have been rejected by aerospace manufacturers building rockets, it also has a higher weight, and when you consider how much wiring there is a rocket, significant weight savings can be made using the lightweight materials.

Ground support equipment may have used non-aerospace spec materials.