posted 05-07-2018 09:52 PM

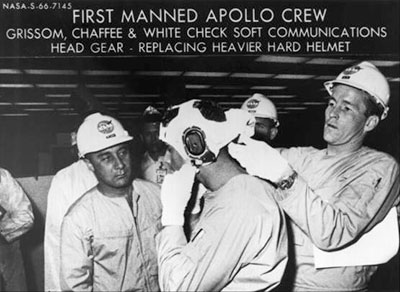

The Apollo 1 type helmets were very close in width dimension to the Gemini G4C helmets, which were the widest of the Gemini hard-shell pressure helmets due to the extended EVA visor pivots. Although the actual pressure shell was the same size for the two helmets, as pointed out the addition of the unique Apollo visor guard and the Gemini parachute riser guard added width to the helmets.

Measuring the overall widths of the helmets indicates the widths only differ by 0.14 inches with the Apollo 1 (A1C helmets) being wider. So they are very close.

As mentioned above, the ridges provided reinforcement since the vacuformed visor guard was very thin. The top ridge provided clearance for the visor latch when the visor was in the open position.

The Apollo 1 style visor guard was developed to provide bump protection for the visor when in the open position. During weightless conditions in the Apollo capsule, the astronauts could float freely whereas the Gemini crews could not move freely enough to develop sufficient speed to cause substantial impact damage to the open visor.

The Apollo 1 style visor guard served a different function than the over-shells on the later used bubble helmets. The over-shells on the bubble helmets were developed to provide attachment points for the EVA visors and also later to provide a surface for TMG attachment.

The over-shell EEVA that was developed for the Apollo A5L development suit (that later evolved into the LEVA an SEVA) was already in existence when the Apollo 1 helmets were developed so the Apollo 1 visor shell did not evolve into the extra vehicular visor assembly but was a separate development to solve a different problem.

The bubble helmets also had their own protective shell that was used for pre-launch entry to the spacecraft, and possibly for in-flight tunnel transition to the LEM to protect the helmet from damage.

Single piece bubble helmets are preferred over helmets with opening visors due to the possibility for leaks during EVA. A large visor opening has a greater potential for leaks due to the length of the sealing surface around the opening of the visor, and is more susceptible to impact damage than a single piece dome.

Any penetration through the suit pressure layer is a point for potential leaks, so there is a strong desire to keep the size and number of openings to a minimum. However launch/entry requirements are different than EVA requirements.

Bubble helmets were not used for the shuttle launch/entry suits primarily since a bubble helmet requires gas flow to the suit anytime the helmet is on.

The shuttle ECS was not designed to handle a closed loop suit circuit nor an open loop suit circuit that exhausted for long periods of time into the cabin.

Thus a bubble helmet could not be used for the shuttle unless it was not donned until needed. If the bubble helmet was off it takes a lot more time to get the helmet and put it on and then start gas flow.

The open visor helmet provided a rapid emergency response alternative. It can be worn with visor open which allows the crew to be fully suited but not using suit oxygen, but ready to go in the event of an emergency.

An open visor helmet is also preferred for comfort when using purely as a backup system (ie launch/entry) as it is more desirable to have the face area open until actually needed.

(However, as it turned out, the desire to minimize oxygen enrichment of the shuttle cabin affected when the visors were closed, which impacted the effectiveness of the suit.)

The down side, as was pointed out, was that since the Shuttle open visor helmet was a large non-conformal helmet, it did not move with the head so that to look sideways the crew had to grab the neckring of the helmet and turn the helmet.

Normal conformal helmets with opening visors fit tightly to the head so that he helmet turns with the head.

The larger non-conformal open visor helmets were chosen for comfort over a tight fitting conformal helmet.

I agree, to me it would be distracting to have the grab the helmet to turn it.