|

Author

|

Topic: Apollo command module inner structure

|

Apolloman

Member Posts: 231

From: Ledignan, Gard (30), France

Registered: Mar 2009

|

posted 05-24-2024 02:50 PM

posted 05-24-2024 02:50 PM

I recently went back to reading Apollo Training structures and Mechanical Subsystems (course number A-512S) and I found a passage that I don't understand, if anyone could enlighten me on the subject... The inner face sheets of the honeycomb sandwich are welded in all case to the solid aluminium members. Thus, the entire inner mold line of the inner structure is a welded inner face mold line, keeping constant with the pressure holding specifications of the craft. Is the word group "inner mold line" which is a problem for me because I can't find a match in French. There is one "ligne de moulage" but that has nothing to do with the subject, this is a term used in the field of injection molding which defines: Weld lines for injection molding refer to a line on a mold. injection-molded part that is generated at the point where the two halves of the mold meet. As a result, the portion has a slight, even undetectable line. Could someone please explain. Thanks in advance. |

space1

Member Posts: 944

From: Danville, Ohio

Registered: Dec 2002

|

posted 05-24-2024 03:32 PM

posted 05-24-2024 03:32 PM

The "inner mold line," abbreviated IML, is the inner face of the structure. The paragraph is referring to the inner pressurized surface of the Command Module.In contrast, the "outer mold line" or OML, is the outer surface of the structure. |

Apolloman

Member Posts: 231

From: Ledignan, Gard (30), France

Registered: Mar 2009

|

posted 05-24-2024 05:40 PM

posted 05-24-2024 05:40 PM

Thank you for the answer.If I've understood correctly, IML is the welded part and OML is the part bonded to the honeycomb. By the way, what was the thickness of the welded and externally bonded sheet metal? |

Apolloman

Member Posts: 231

From: Ledignan, Gard (30), France

Registered: Mar 2009

|

posted 06-20-2024 02:50 AM

posted 06-20-2024 02:50 AM

Thanks to the information I've gathered, I've been able to rewrite the page on my site devoted to the internal structure of the Apollo CM, even adding a "video medley" featuring several sequences from other videos, as well as numerous photos tracing its manufacture chronologically. (It's in French, but the images have no language barrier.)However, because I like to get things right, I'm missing an important piece of information: the thickness of the sheet metal or aluminum foil used in its manufacture: the welded ones for the inner shell and those of the outer skin (glued to the honeycomb). Thickness is important to be able to use the right term: sheet or foil. |

Jim Behling

Member Posts: 1928

From: Cape Canaveral, FL

Registered: Mar 2010

|

posted 06-20-2024 07:55 AM

posted 06-20-2024 07:55 AM

quote:

Originally posted by Apolloman:

Thickness is important to be able to use the right term: sheet or foil.

No foil was used in the structural elements of any Apollo spacecraft. Sheet is not even the proper term, it would be panel. |

Axman

Member Posts: 489

From: Derbyshire UK

Registered: Mar 2023

|

posted 06-20-2024 11:38 AM

posted 06-20-2024 11:38 AM

Was gold foil not used as a structural element in the Apollo LMs? And wasn't Kapton foil a structural element utilised on Apollo CSMs? |

Apolloman

Member Posts: 231

From: Ledignan, Gard (30), France

Registered: Mar 2009

|

posted 06-20-2024 12:15 PM

posted 06-20-2024 12:15 PM

quote:

Originally posted by Jim Behling:

Sheet is not even the proper term, it would be panel.

I understand perfectly what you write, but isn't the panel made up of an outer face and an inner face with a honeycomb core?And it's precisely the thickness (to approximate as closely as possible) of these faces that I'm trying to find out, given that the entire inner shell is welded. |

Jim Behling

Member Posts: 1928

From: Cape Canaveral, FL

Registered: Mar 2010

|

posted 06-20-2024 01:36 PM

posted 06-20-2024 01:36 PM

quote:

Originally posted by Apolloman:

...but isn't the panel made up of an outer face and an inner face with a honeycomb core?

Sheet or face. quote:

Originally posted by Axman:

Was gold foil not used as a structural element...

Not structure but insulation in both cases. |

Apolloman

Member Posts: 231

From: Ledignan, Gard (30), France

Registered: Mar 2009

|

posted 06-20-2024 02:07 PM

posted 06-20-2024 02:07 PM

quote:

Originally posted by Jim Behling:

sheet or face

Have you seen my web page dedicated to the subject? At the very beginning there is an animation showing roughly the formation of a panel.We have a first sheet or plate (still depending on the thickness I don't know) as a base, then an adhesive bond, then comes the honeycomb core, again an adhesive bond and finally a new sheet or plate which is the external coating. As can also be seen at the very end of the video, where an African-American technician positions the aluminum strip used to cover the circumferential weld seam. So it's the thickness of this material that I'm looking for, whether it's the outer skin, or the one used for the fully welded shell underneath (which you can see in the first few seconds of the video... To the sulfuric acid bath for anodizing). Sorry if I'm expressing myself badly, but I'm not in English. |

SpaceAholic

Member Posts: 5366

From: Sierra Vista, Arizona

Registered: Nov 1999

|

posted 06-20-2024 09:24 PM

posted 06-20-2024 09:24 PM

|

Apolloman

Member Posts: 231

From: Ledignan, Gard (30), France

Registered: Mar 2009

|

posted 06-21-2024 01:00 PM

posted 06-21-2024 01:00 PM

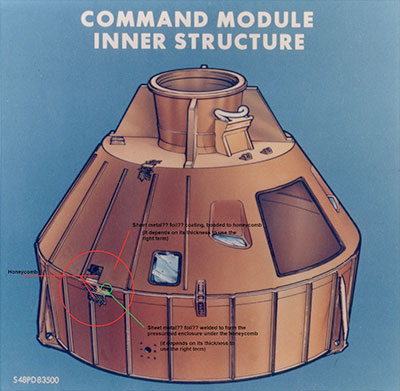

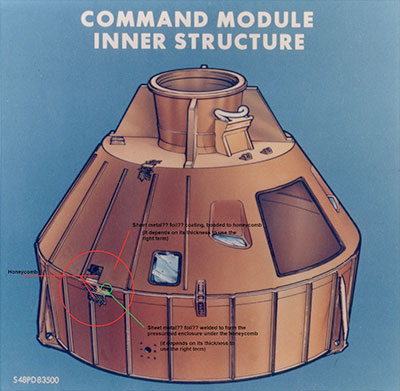

Thank you, but what you're showing us here (if I'm not mistaken), while still interesting, is only the complete structure of the heat shield and not that of the pressurized inner structure (crew compartment).You can see the stainless steel parts (which were brazed rather than bonded, as in the crew compartment's internal structure) and the ablator-filled honeycomb. On a previous post I had opened, you had even given me the thickness of the sheet metal (sheet metal because 1,90 mm thick) used with a caliper. Thanks for the effort. I'm looking for this (maybe a drawing will help me make myself understood):  |